Spare Parts

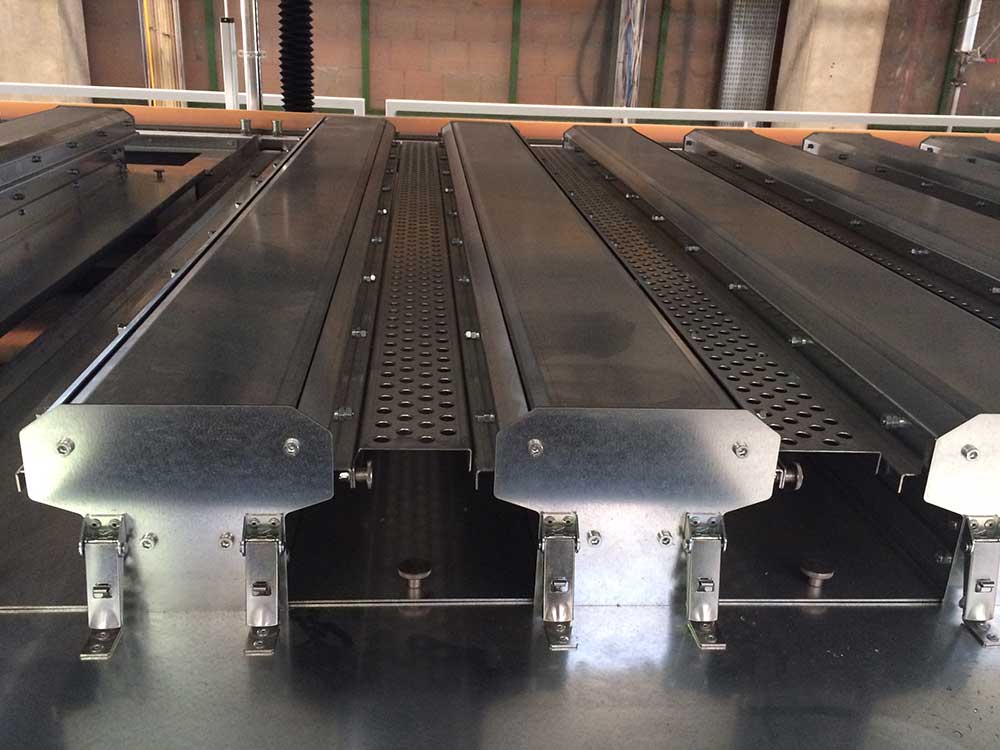

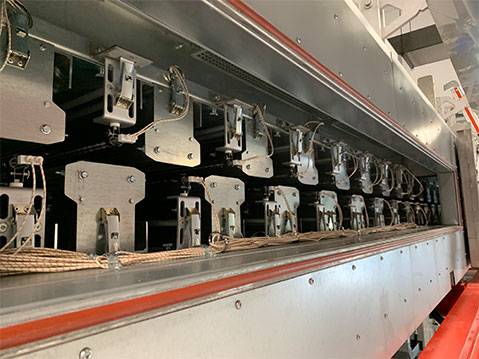

Drying tunnel

Design and construction of a wide range of drying tunnels for the drying of water and solvent-based coatings.

The proposed solutions guarantee maximum drying performance with uniform distribution of supply and exhaust air and temperature along the entire section of the tunnel.

Photo gallery

Additional configurations and equipment

They can also be used to cool the previously coated and dried backing by sending air at room or cold temperature (by a chiller).

Additional equipment:

- Sensors for measuring process air humidity

- Sensors for measuring the temperature of the coated material

- Sensors to detect the solvent concentration inside the tunnel

The nozzles are easily removable for cleaning and interchangeability and we can propose three configurations:

- Impingement

- Floatation

- Vacutex®

Possibility of inserting a heat exchanger for energy recovery.

Process air heating via:

- Electricity

- Gas

- Diathermic oil

System advantages

- High efficiency

- Absence of lateral air flows with consequent improvement in safety conditions in the case of solvent-based coatings

- Low energy consumption

- Perfect web handling

- Optimal air distribution both transversally and longitudinally

- Maximum accessibility for maintenance and cleaning operations

- Clear separation of upper and lower air flows