Converting lines

Slitter rewinders for paper, films and aluminum

Slitting and rewinding lines for flexible packaging with the following configurations:

- Twin-shaft slitter-rewinder

- Double rotary turret slitter rewinder with automatic splice

- Central drum slitter rewinder

- Slitter rewinders with center-peripheral rewinding

Photo gallery

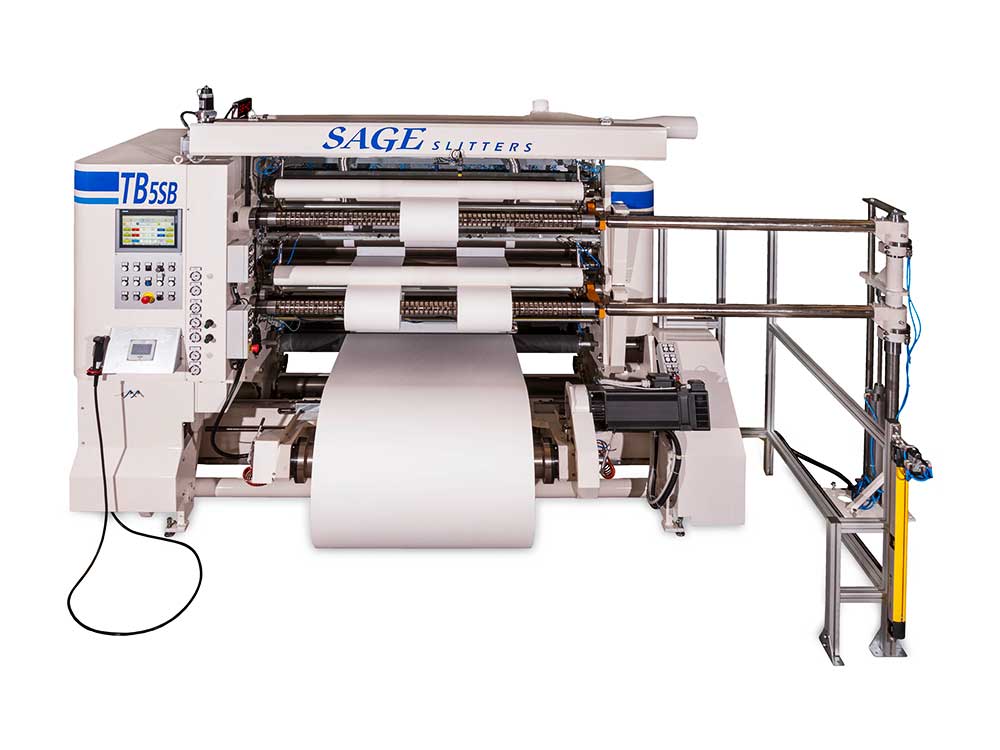

Double shaft slitter rewinder

- Winding on expandable or differential friction shafts

- Web path on the floor or on the bridge

- Slitting with razor blades or circular knives

- Manual or electric reel unloading system

Optional:

- Splice table

- Trim exhauster

- Automatic knife positioning system

- Automatic core positioning system on the rewinding shafts or, alternatively, laser pointer for core positioning by the operator

Double rotary turret slitter rewinder with automatic splice

- Winding on expandable or differential friction shafts

- High productivity line

- Extremely versatile for long productions or for quick winding of short lengths

- Eliminates machine downtime for unloading reels.

Optional:

- Splice table

- Trim exhauster

- Automatic knife positioning system

- Automatic core positioning system on the rewinding shafts or, alternatively, laser pointer for core positioning by the operator

Central drum slitter rewinder

Central drum slitter rewinders with centre-peripheral rewinding.

Suitable for all types of rigid or elastic materials, even with non-uniform thicknesses.

Particularly suitable for the need for independent control on each end reel.

Slitter rewinders with center-peripheral rewinding

Slitter rewinder with central drive rewinding with overhead film passage. Independent rewinder stations with individual pressure roller.

The unloading system, the automatic positioning of the slitting units as well as of the rewinding units and the high degree of automation of this machine offer the possibility of obtaining high production performance and very high quality standards.

Optional:

- Splice table

- Trim exhauster

- Automatic knife positioning system